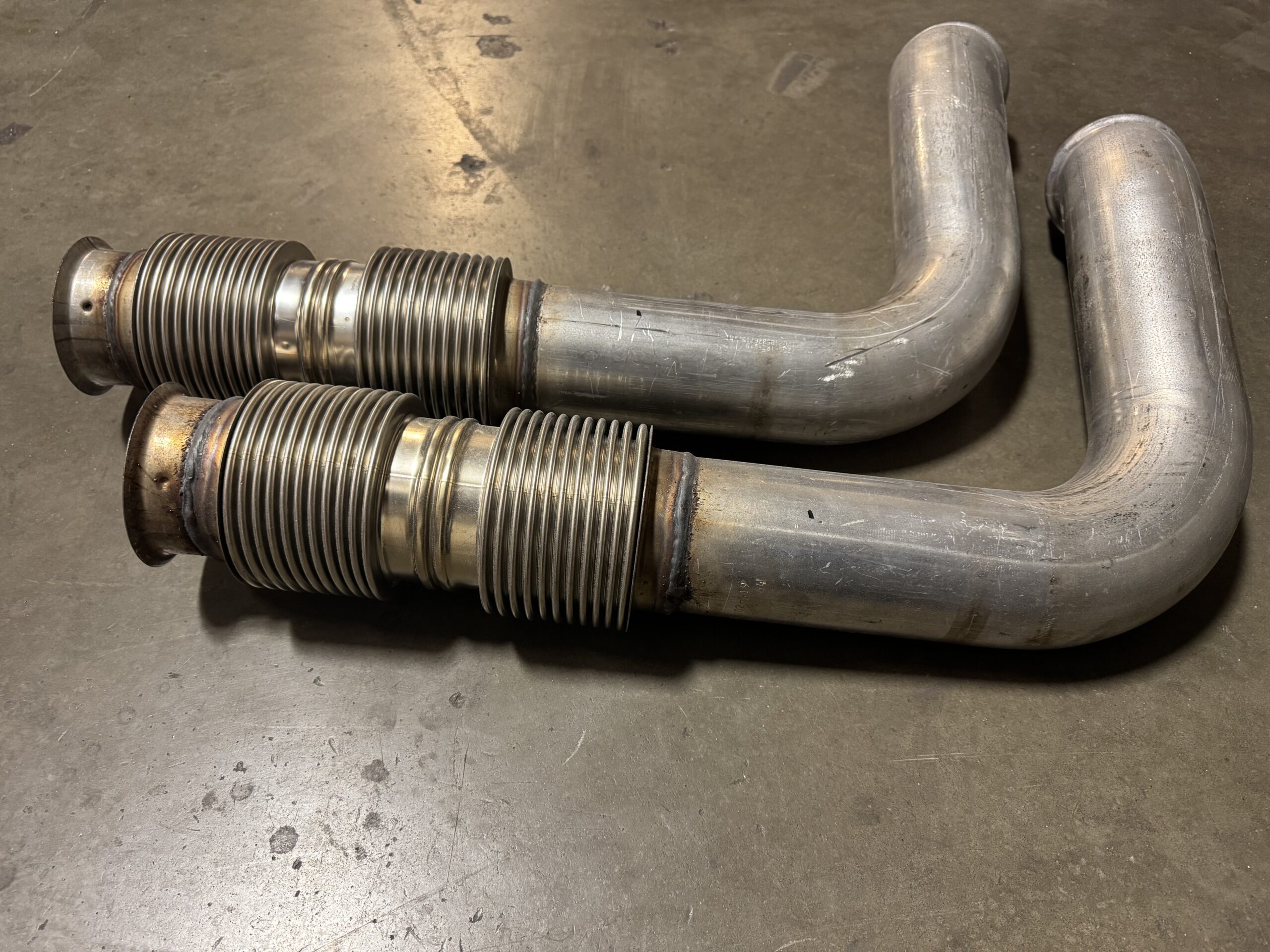

Stainless Steel Bellows

Our stainless steel bellows, available in sizes ranging from 1-1/2″ to 3″ (with special orders for 4″ and 5″), are engineered based on proven designs from the heavy-duty industry, including applications on semi-tractors, dump trucks, and agricultural tractors. This robust design offers a dependable, heavy-duty solution for our customers. Unlike traditional flex tubes that prioritize flexibility but are prone to failure under stress, our bellows provide superior durability and resilience, ensuring long-lasting performance even in demanding conditions.

What are Bellows?

A flexible, accordion-like component commonly used in exhaust systems, designed to absorb engine vibrations, thermal expansion, and movement. This essential part ensures smooth operation by reducing stress on exhaust piping, effectively serving as a flexible joint between various sections of the exhaust system for improved performance and durability.

How to effectively use stainless steel bellows.

Place the bellow on a horizontal section of the exhaust, either before or after a clamp, and near bends greater than 40 degrees. If you need more flexibility, you may need to add extra stability* (read below) to your exhaust or stack multiple bellows. When stacking, leave a minimum of 1/4 the length of each bellow as space between them. For example, if the bellow is 1 inch long, there should be at least 1/2 inch of material between the two bellows.

*Having too much movement in your exhaust system can lead to several problems, including:

Increased Wear and Tear: Excessive movement puts stress on joints, flanges, and other components, causing them to wear out faster or fail prematurely.

Exhaust Leaks: Frequent or uncontrolled movement can loosen connections, leading to gaps that cause exhaust leaks, reducing performance and increasing noise.

Damage to Adjacent Components: An overly flexible exhaust system can sway or vibrate excessively, potentially damaging nearby parts, such as fuel lines, wiring, or the vehicle’s undercarriage.

Decreased Durability: The materials in the exhaust system are designed to handle specific stress levels. Increased movement can weaken these materials over time, shortening the lifespan of the system.

Performance Issues: Excessive flexibility can interfere with the proper alignment of the exhaust system, affecting flow efficiency and reducing engine performance.

By maintaining proper stability in your exhaust system, you can ensure longevity, safety, and optimal vehicle performance.